A Look at 2023: Laser Manufacturing and What You Should Know

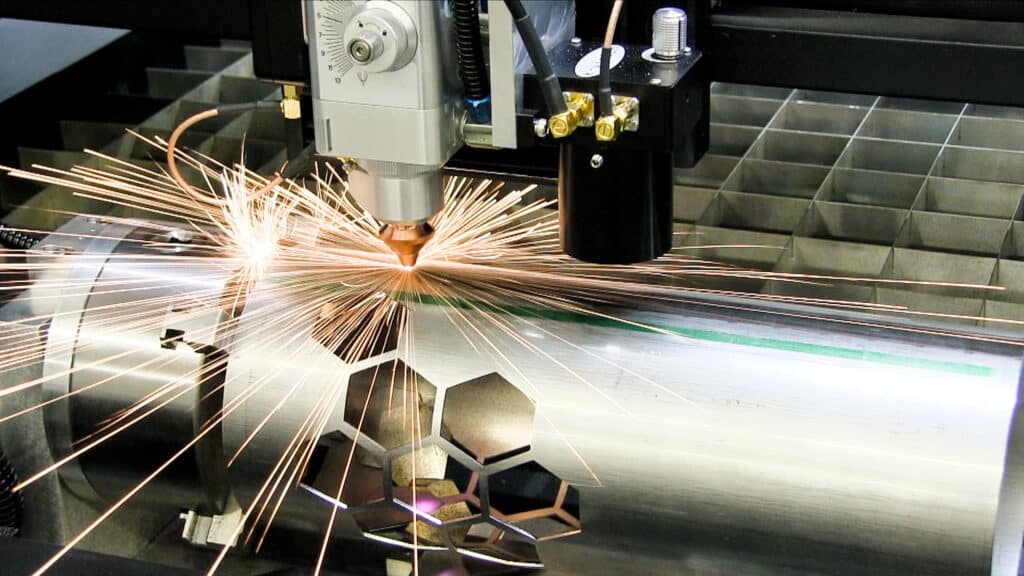

The story of laser manufacturing in 2023 and beyond looks to be one of continued growth in spite of lingering economic headwinds from pandemic recovery, supply chain challenges, and the general economic volatility of recent years. What trends and changes in the laser manufacturing industry are likely in 2023? The fiber laser industry is predicted to grow by approximately 880 million dollars between 2022 and