ACRYLIC CUTTING LASER

Acrylic Etching and Cutting Equipment

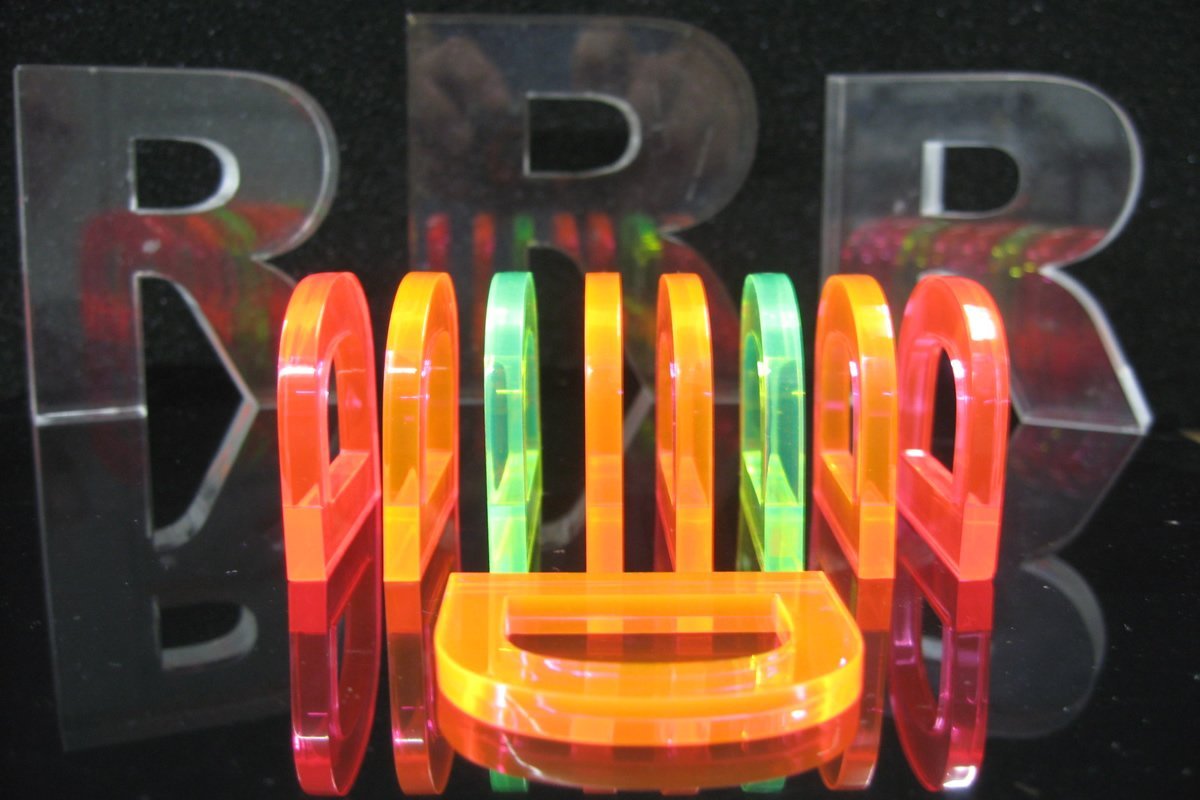

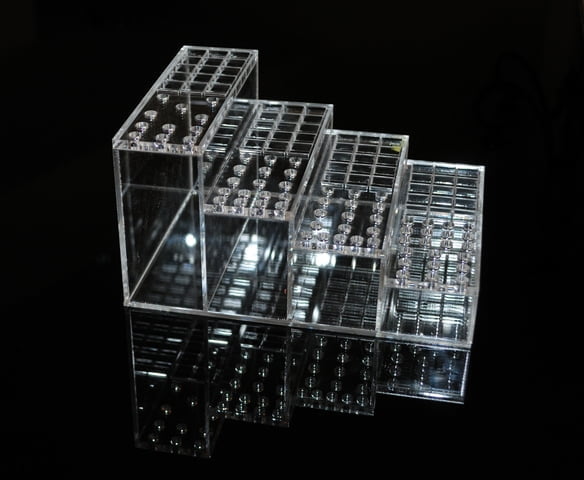

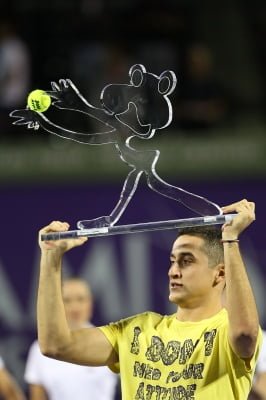

Laser cutting systems, offer greater speed, precision and quality than traditional processing equipment. Our advanced laser cutting systems are designed to revolutionize your creative and industrial projects, offering exceptionally fast processing times that boost efficiency without sacrificing detail. Experience the unique advantage of flame-polished edge quality, ensuring each cut is smooth and visually stunning. Moreover, our systems excel in delivering frosty white etching, perfect for adding intricate details or sophisticated finishes to your designs. Whether you’re crafting intricate art pieces, functional prototypes, or custom signage, our acrylic laser cutting technology is engineered to elevate your projects with speed, precision, and a touch of elegance.

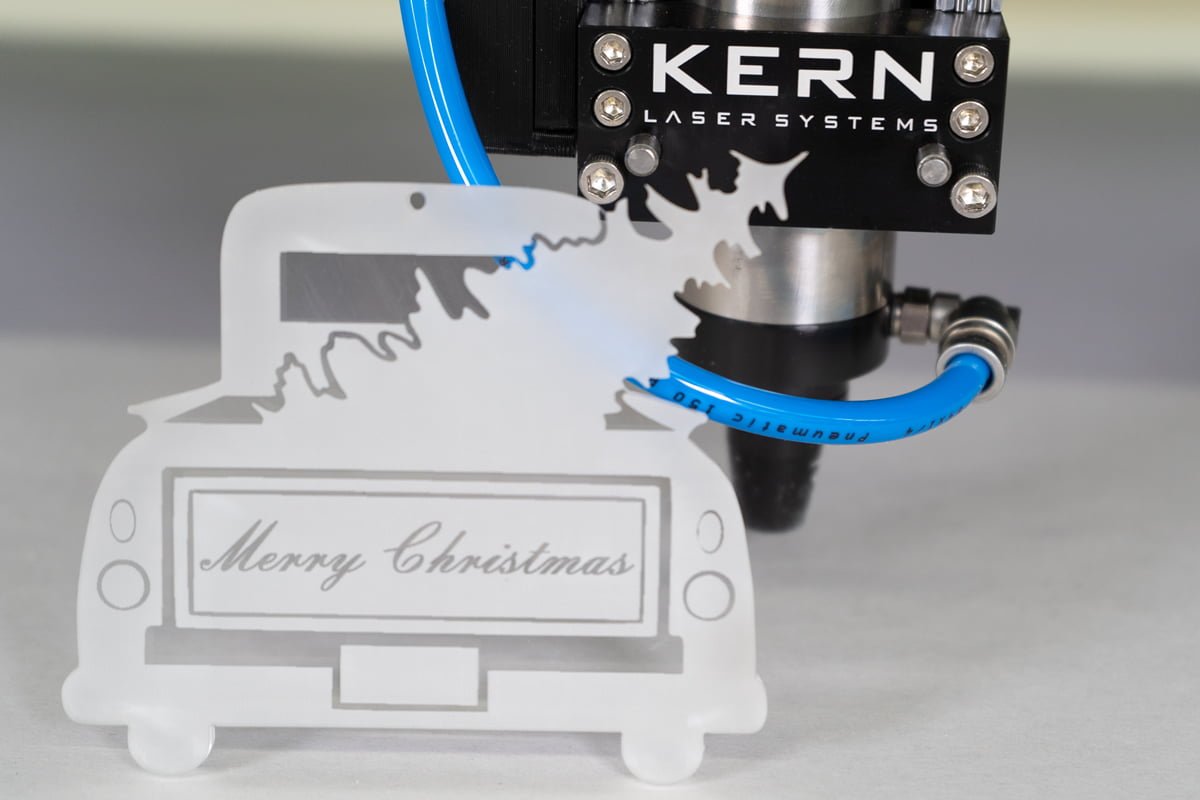

Kern’s interchangeable lens assemblies provide laser beam characteristics required to achieve straight cut edges with a single pass of the laser beam. Shorter focal length lenses provide a smaller, super concentrated beam capable of etching ultra-small text with a frosty white mark on clear acrylic.

Benefits of a Laser System

Acrylic by nature can scratch easily if not handled properly. Laser cutting and engraving is a non-contact process, allowing acrylic to be cut without tooling which comes in contact with the material and can damage the surface of the acrylic.

Kern’s CO2 lasers cut acrylic with a single pass of the laser beam resulting in a flame polished edge quality that does not require post processing steps such as buffing or manual flame polishing of the processed edge.

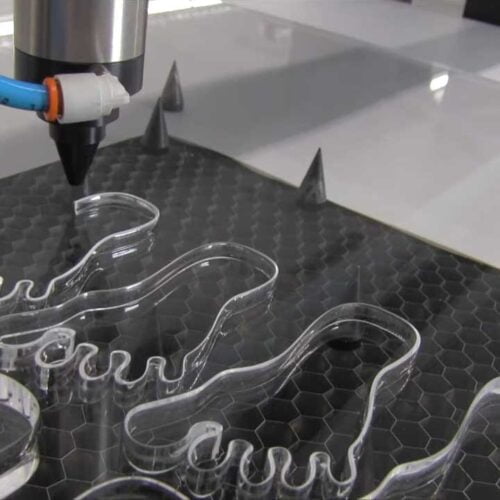

The CO2 laser beam has a kerf as small as .005″, allowing parts to be nested tightly together maximizing sheet yield and reducing waste. Nesting software is available which will automatically nest complex parts together saving you money on each job you run.

Tips and Tricks

Nozzle Size Matters

When acrylic is cut or engraved a foggy appearance may be noticed around the processed area. This is most likely cause by too much concentrated air flow delivered to areas of the acrylic sheet that are still molten. To eliminate or greatly reduce this occurrence try using our wide nozzles. The larger nozzle orifice allows the assist air to be dispersed over a larger area eliminating the foggy appearance.

Tick Marks

Another common complaint we receive from customers is the appearance of tick marks on the back side of acrylic sheet after it has been cut. These tick marks are caused by the laser passing over areas that the acrylic is in contact with the aluminum honeycomb bed. Kern has developed several bed options which will reduce or eliminate these tick marks. Try using our paper honeycomb, rubber/aluminum spacers or acrylic slat table